Projects – Engineering, design and delivery for Projects on both greenfield and brownfield sites

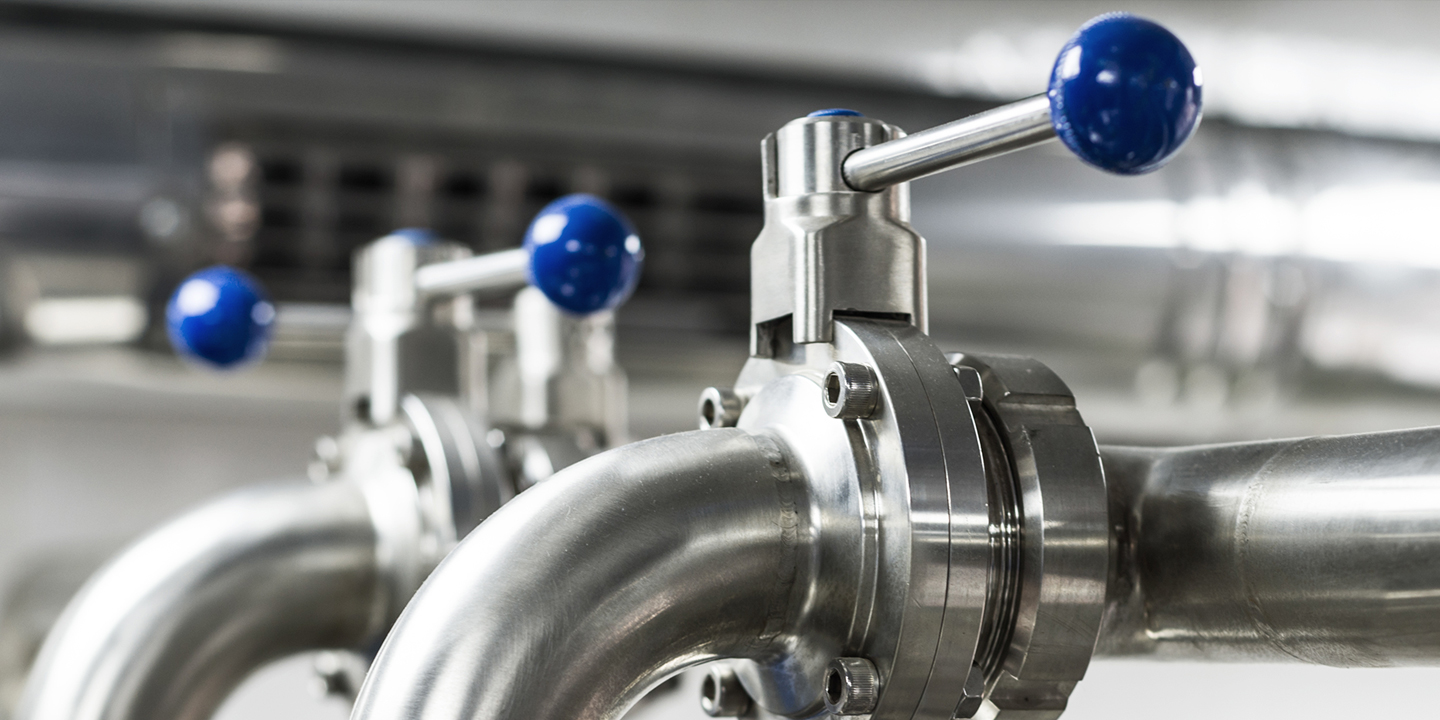

WorkShop – Engineering, design, fabrication and certified welding with stainless steel, aluminium and other exotic materials

On-Site Installation/Maintenance – Provide on-site crews for long and short-term maintenance contracts, small projects, refurbishments and shutdowns

Site Installation, Relocation Works, Commissioning

We take the time to understand our clients’ unique project requirements with a flexible and innovative approach. Our experienced staff are from a wide range of specialist trades and have the ability to successfully complete your project.

Our guaranteed quality workmanship and client satisfaction ensures a smooth integration between BDR/client/project.

Fabrication

Our Brisbane workshop is well equipped with the latest machinery. Our well-appointed team has the ability to fabricate to our clients requirements. We apply strict Quality Assurance throughout the life cycle of each project including in-house weld procedures, ITP and MDR’s where required.

Modification & Maintenance Contracting

BDR has excellent mechanical installation knowledge and experience. We have the ability to work within clients needs and have an in-depth understanding of production area requirements to ensure minimal downtime.

Orbital Welding

The term “Orbital Welding” is based on the latin word ORBIS = circle.

The combination “Orbital” and “Welding” specifies a process by which an arc travels circumferentially around a work piece (usually a tube or pipe).

Orbital Welding is presently used whenever the quality of the weld joint has the highest priority. These demands are not only limited to mechanical strength and X-ray qualification, but also to the important aspects of the aesthetics of the weld seam. For any users a uniform, flat and smooth root-pass is the main reason for using this process.

Equipment

BDR Stainless has a well equipped workshop in Tingalpa. We also have site mobilisation equipment

which is available to assist in delivering our products and services at our clients premises

- Break Press 4 meter by 250t

- Guillotine 3 meter by 12 mm capacity

- Punch and Shears (100t and 45t)

- Section Rollers (80t)

- Plate Rollers

- Orbital Welders

- Pulse Welding Machines (TIG & MIG)

- Centre Lathes 2 metre

- Hydraulic Press (200t)

- Hydraulic Pan Break

- Milling Machines

- Mobile Diesel Welding Equipment

- Generator Sets

- Mobile Site Workshops

- Fully Equipped Site Vehicles